Challenges and Solutions

The Swiss SME greenTEG develops, manufactures and markets heat flux sensors for applications in research and development, building physics and laser beam characterization. The thermal laser power sensors are integrated into laser systems in materials processing, medical technology and scientific setups. The products are optimized for OEM integration into systems and are used to detect laser power and laser beam position at various power levels.

With its existing technologies and products, the SME can play a major role in the continuously growing market of fiber lasers. As greenTEG is specialized in OEM component design, the company needed additional competences for moving their products from applications in free-space optics to the fiber laser market – this was the challenge to be solved with the support of the gateone-project.

Smarter-SI Support

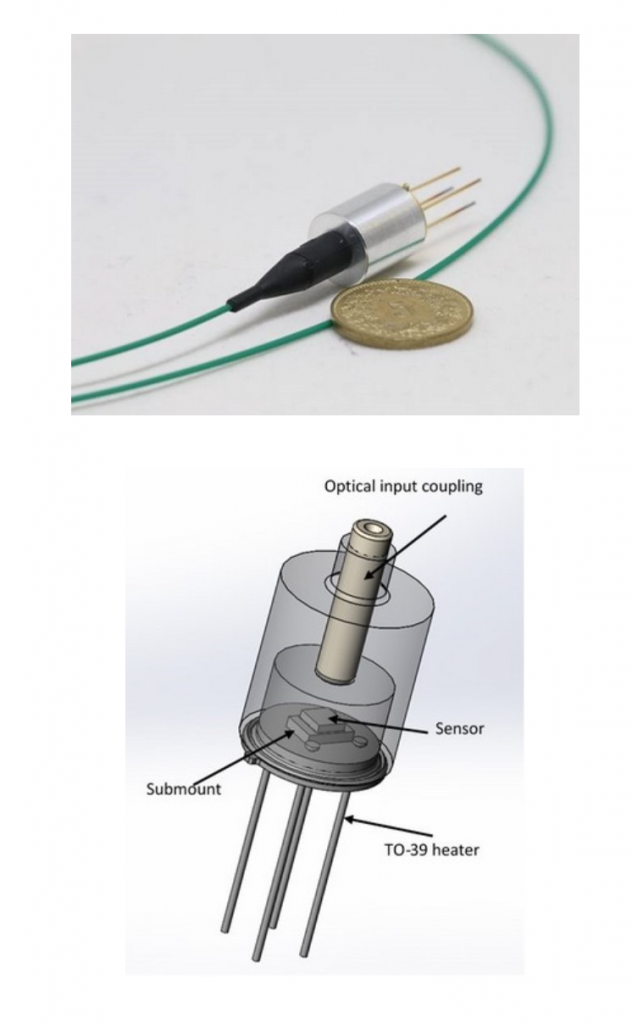

For successfully entering the optical fiber market, greenTEG had to develop components that are compatible with the fiber optics approach in a “plug and play” design. Through the gateone-project, CSEM, a Swiss research organization (RTO) focusing on electronics and microtechnology, helped the SME by adaption and implementation of CSEMs advanced photonics packaging technology. This way the RTO enabled a cost-effective, fiber coupled detector with a high resistivity against environmental influences. Unmatched performance is achieved in wavelength coverage from UV (400 nm) to MIR (2200 nm), mainly limited by the attenuation of the silica fiber used, for optical signals up to 500 mW and a resolution in the sub mW range.

Impact/What’s next

With the photonic packaging technology, greenTEG will target new markets with a widespread range of applications, most notably fiber-coupled laser systems with wavelengths in the mid-infrared range.