Challenges and Solutions

With actual spirometry systems the breath of a patient is not monitored directly at his mouth. The air needs to go through long tubes to a complex and relatively cost intensive apparatus that analyses the breath amount and frequency, but does not analyse the composition of the breathing gas.

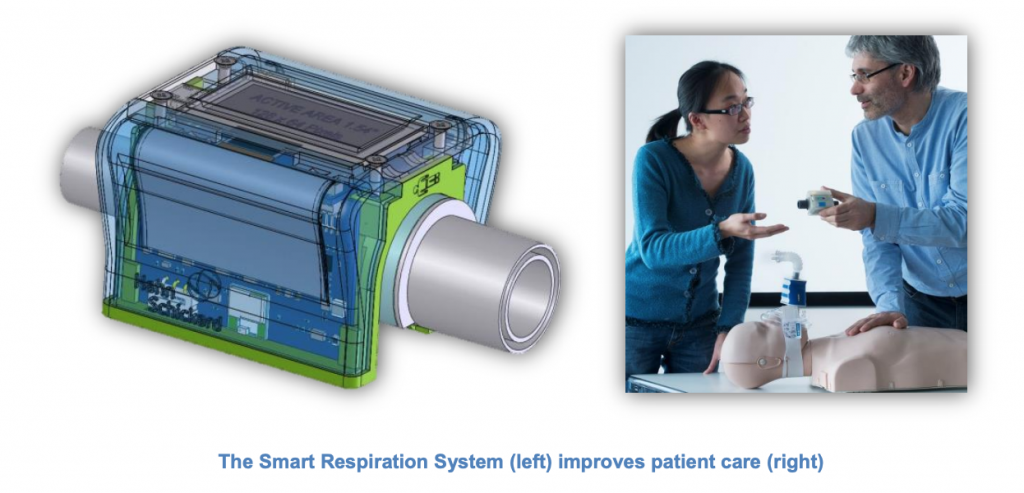

Within the SMARTER-SI project a new type of respiration system will be manufactured that combines electronics as medical device (regulated market) with respiration tubes as disposable (low price!).

The main advantages are:

- Safe measurement of CO2 concentration and flow in the moist breathing gas with thermal

- MEMS sensors patient-side directly on the mouthpiece with minimal dead volume

- Increase of the device security by reducing the complexity of patient hoses

- Expandable sensor platform with a high integration density allows easy integration into other systems, as well as an expected reduction in price, thus enabling new applications

The manufacturing is a challenge due to the complexity and high miniaturization of the module while considering medical exigencies.

Smarter-SI Support

The project partners of SMARTER-SI can provide all necessary technologies and building blocks to realise this innovative sensor system with the desired TRL: A temperature sensor (building block by CiS) and MEMS-sensor elements for flow and CO2 (building block by Hahn-Schickard) using assembly technologies by IK4-IKERLAN and Tyndall National Laboratories. The electrical contact system for medical application to connect the disposables is provided as building block by Swerea IVF.

Impact/What’s next

The German SME Karl Küfner contributes e.g. housing, tubes and tools for the production of the disposables. The company, as specialist in injection molding technology and biocompatible materials, will also implement the end-user testing and the commercialisation of the final product.